Peinture A3M is specialised

Metal pretreatments

The metal pretreatment is unquestionably the most important step in the process electrostatic powder paint application.

It helps to prepare to receive the metal powder paint application by providing him with maximum adhesion.

A3M Paint provides several types of pretreatments and are used depending on the type of parts, and / or the degree of quality required with respect to the salt spray resistance ASTM B117 standard.

We offer the following pretreatments; chemical pretreatment using a new zirconia generation. That is products have the advantage of being great in the pretreatment of steel and aluminum, while being much less polluting than conventional phosphate pretreatment of iron or zinc.

We also offer the mechanical preparation service; sandblasting sand blasting (sandblast), sandblasting the aluminum oxide (oxyblast), and grit blasting the glass ball (glassblast).

Zirconium chemical metals pretreatment

Our zirconium chemical pretreatment in 3 stages is automated, which allows for consistency in the pretreatment time, as well as the ideal temperature of the products and an adequate rinsing.

This cutting edge process allows us an excellent preparation of surface before applying the paint by electrostatic powder.

Zirconium products and aditit used by Peinture A3M provides a dual chemical action by cleaning and applying a layer of Zirconium before applying the paint.

They are formulated to mix well with some regions hard water. They prevent surface rust even on hot-rolled steels.

The two products will create a complex Zirconium oxide layer that will provide excellent paint adhesion and corrosion resistance. They contain much less phosphate than the dual action iron phosphates.

The two products are designed to be pre-treated steel, zinc and aluminum alloys.

Mechanical pretreatments

Sandblasting

Sandblasting is an industrial technique for cleaning large surfaces using an abrasive projected at high speed by means of compressed air through a nozzle to the material to be stripped. Peinture A3M provides sandblasting service.

Sandblasting is used in many industries to prepare surfaces prior to electrostatic powder paint application.

- It scours, deoxidizes, removes a fragile surface layer (paint for example).

- It creates a roughness which facilitates the adhesion of a coating, which gives a good preparation prior to painting.

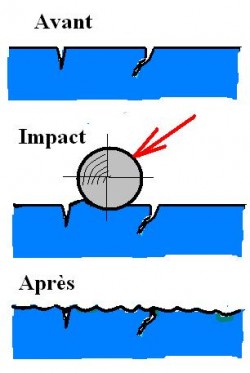

Blasting (Shotblast)

Shot blasting is a technique for projecting, with a blasting machine, microbeads on the surface of an object to modify the surface structure. The desired goals are:

- surface treatment to improve the appearance, technique similar to sand blasting,

- preload or shot peening to improve the technical quality of surfaces.

It’s a continuous projection at high speed, up to 100 m/s, of small steel, glass or ceramic balls on the surface of the workpieces.

The required result depends on several factors:

- the nature of the material to be treated,

- the nature and size of the granules,

- the flow rate and the impact velocity,

- the jet direction.

There are two spraying processes:

- The pneumatic projection, the shot is then mixed with the compressed air, and screened by a flexible ending in a nozzle, the operator aims the workpiece. The air blasting can for example be made in cabin. It has the advantage of being targeted.

- The mechanical projection, for example a blasting machine turbine. An impeller rotates at high speed, is fed by the media center, the centrifugal force projects the shot and form a curtain treating parts.

Advantages

- requires no income after treatment

- only slightly deforms the parts,

- improves the durability and the resistance to fatigue of the parts (up to 10 times for a helical spring),

- enables the design of lighter and less expensive parts,

- provides additional corrosion protection,

- neutralizes foundry rough surfaces defects

- as microscopic lubricating pockets,

- applies to different types of metal (steel, cast iron, bronze, aluminum, magnesium),

- reuse microbeads after cleaning.

Shot blasting cleaning is intended to:

- remove rust, mill scale and other impurities to obtain a finished surface or a preparation before covering thereof by a protective layer such as paint,