Peinture A3M is specialised in

Powder coating

The specialty of Peinture A3M is the application of powder coating with thermostatic process. The coating is applied electrostatically and forms a “skin” under heat.

Our 3 stages washing process uses a zirconium as a pre-treatment as well as 2 rinsing cycles to adequately prepare different materials (steel, aluminum and stainless steel) before painting. The removal of oil, dirt and other greases is essential before applying the powder coating process. This pre-treatment process allows cleaning and improving the adherence of the powder to the metal.

We are equipped with a 20 ‘X 25’ paint shop with closed filtration system to eliminate risk of color contamination. This room is also equipped with air filtration and breathable air unit for the painters. The powder coating can be applied appropriately.

Our painters are equipped with a breathing air system with carbon monoxide detector which makes it a safe and comfortable working environment for the application of the powder.

Our 24’ long oven can accommodate pieces of small and large format.

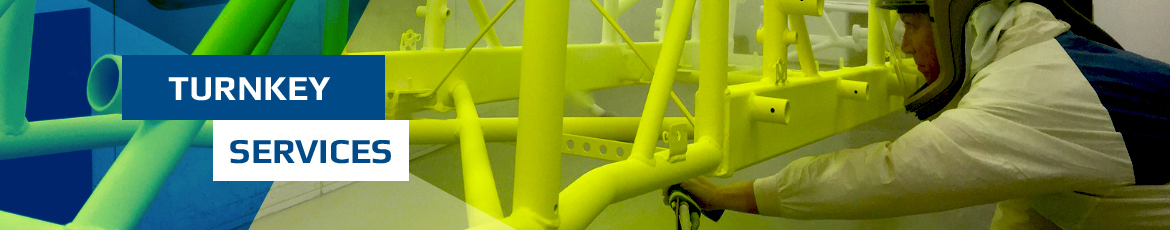

Turnkey solution

Blasting (sandblast, glass beads and aluminium oxyde)

Convinced that a turnkey solution is advantageous for its customers, A3M Painting offers additional services that reinforce its position as a leader in its field.

Offering the service of sandblasting sand, glass beads and aluminum oxide, the company once again demonstrates its desire to innovate and adapt to the needs of manufacturers, thus creating a link increasingly strong partnership.